Water, the lifeblood of humanity, sustains us all and is fundamental to our existence. The purity and safety of our drinking water are paramount for our well-being. However, lurking within the complex network of plumbing lies a hidden danger – backflow. Backflow, the undesirable reversal of water flow, can jeopardize the integrity of our clean water supply and expose us to potential health hazards. This is where the crucial role of backflow prevention comes into play as a guardian of our water quality.

Backflow incidents can occur due to changes in water pressure, resulting in the contamination of the clean water supply with non-potable water, pollutants, chemicals, and harmful bacteria. The thought of unwittingly consuming harmful substances while taking a simple sip from the faucet is a risk too great to overlook. That’s why backflow prevention stands as a stalwart defender of our water quality, ensuring that we can enjoy safe and uncontaminated water for all our needs.

In this article, we will delve deeper into the concept of backflow prevention, its significance, and the role it plays in preserving the health and well-being of communities. We will explore the dangers posed by backflow, the types and workings of backflow preventers, and the importance of regular maintenance and compliance with regulations. Additionally, we will provide valuable insights into the specific importance of backflow prevention for residential, commercial, and industrial settings.

Let us embark on a journey to understand the essence of backflow prevention and how it contributes to securing our access to clean and uncontaminated water, protecting us and our loved ones from potential waterborne threats.

What is Backflow and How Does it Happen?

Backflow is the undesirable reversal of water flow within a plumbing system, leading to the reversal of non-potable water into the potable water supply. It can happen due to back pressure or back-siphonage.

Back-pressure occurs when the pressure of non-potable water exceeds that of the potable water supply, forcing water to flow back into the system. This can happen when there is increased pressure in the non-potable water source, such as in a boiler or a connected irrigation system.

Back-siphonage, on the other hand, happens when there is a drop in the water supply pressure, creating a vacuum that draws contaminants back into the water supply. This can occur when a water main breaks, a hydrant is opened, or when water is withdrawn from the system using a hose or other equipment.

Both back-pressure and back-siphonage scenarios can pose serious threats to the safety of the drinking water supply. Backflow incidents can occur in residential, commercial, and industrial settings, and they are more likely to happen in situations where there is a cross-connection between the potable and non-potable water systems.

Backflow prevention devices, such as pressure vacuum breakers (PVB), reduced pressure zone devices (RPZ), and double check valves (DCV), are essential to safeguarding our water supply and preventing the occurrence of backflow incidents. These devices are strategically installed in the plumbing system to automatically close off the non-potable water source when a reversal in water flow is detected, thus protecting the potable water from contamination. Regular maintenance and testing of these backflow preventers are crucial to ensure their proper functioning and compliance with regulations.

By understanding how backflow can occur and the importance of prevention, we can take proactive measures to protect our water supply and prioritize the health and well-being of our communities.

Understanding the Dangers of Backflow

Backflow incidents can have severe consequences, posing significant risks to both public health and the integrity of our water supply. It is crucial to comprehend the potential dangers associated with backflow to fully appreciate the importance of implementing effective backflow prevention measures.

Contamination of Drinking Water

One of the most alarming dangers of backflow is the contamination of the drinking water supply. When backflow occurs, it can introduce a variety of pollutants, chemicals, and harmful bacteria into the clean water system. These contaminants can originate from various sources, including irrigation systems, boilers, swimming pools, and industrial processes. Once these pollutants enter the potable water supply, they can cause immediate health concerns and pose long-term risks to consumers.

Health Risks

Drinking water contaminated by backflow can lead to severe health issues, especially for vulnerable individuals such as children, the elderly, and those with weakened immune systems. The presence of harmful pathogens and toxic substances in the water can result in waterborne diseases and gastrointestinal illnesses. In worst-case scenarios, waterborne outbreaks can affect entire communities, leading to public health emergencies.

Legal and Regulatory Compliance

In recognition of the potential health hazards associated with backflow incidents, many municipalities and regulatory bodies have enacted strict guidelines and regulations to ensure backflow prevention. Compliance with these regulations is not only essential for safeguarding public health but also for avoiding legal liabilities, penalties, and potential litigation in the event of a backflow-related incident.

Protection of Water Quality

Backflow prevention is integral to preserving the quality of our water supply. Access to clean and uncontaminated water is a fundamental right and essential for maintaining good health and well-being. By implementing effective backflow prevention measures, we can protect the integrity of our water distribution systems and ensure that every drop that reaches our faucets remains safe for consumption.

Environmental Impact

Backflow incidents can also have adverse effects on the environment. Contaminated water that escapes into natural water bodies can harm aquatic life, disrupt ecosystems, and contaminate valuable water resources. Backflow prevention measures not only protect public health but also contribute to the conservation and preservation of our environment.

Understanding the dangers of backflow reinforces the need for proactive backflow prevention strategies. Installing appropriate backflow preventers and regularly testing and maintaining these devices are essential steps in mitigating the risks associated with backflow incidents. By prioritizing backflow prevention, we can ensure the safety, purity, and sustainability of our water supply for generations to come.

The Role of Backflow Preventers

Backflow preventers play a crucial role in safeguarding the integrity of our water supply by preventing the backward flow of non-potable water into the clean water system. These devices serve as a barrier, ensuring that contaminants, pollutants, and harmful substances do not compromise the safety of our drinking water. Understanding the role and importance of backflow preventers is essential for ensuring water quality and protecting public health.

Types of Backflow Preventers

There are several types of backflow preventers, each designed for specific applications and varying levels of protection. Common types include pressure vacuum breakers (PVB), reduced pressure zone devices (RPZ), and double-check valves (DCV).

Pressure Vacuum Breakers (PVB)

PVBs are often used for low-hazard applications, such as residential irrigation systems. They feature a simple design that prevents backflow by creating a barrier when the water pressure drops.

Reduced Pressure Zone Devices (RPZ)

RPZ backflow preventers offer a higher level of protection and are commonly used in commercial and industrial settings. They have a more complex design with two check valves and a relief valve to ensure superior backflow prevention.

Double Check Valves (DCV)

DCVs are frequently utilized in medium-hazard applications, such as fire sprinkler systems. They consist of two check valves, providing an additional layer of protection against backflow incidents.

How Backflow Preventers Work

Backflow preventers operate based on the principle of check valves, which allow water to flow in one direction only. When water flows normally, the check valves in the backflow preventer remain open, allowing water to pass through without obstruction. However, in the event of a change in water pressure that might cause backflow, the check valves automatically close, creating a physical barrier that prevents the non-potable water from entering the potable water supply.

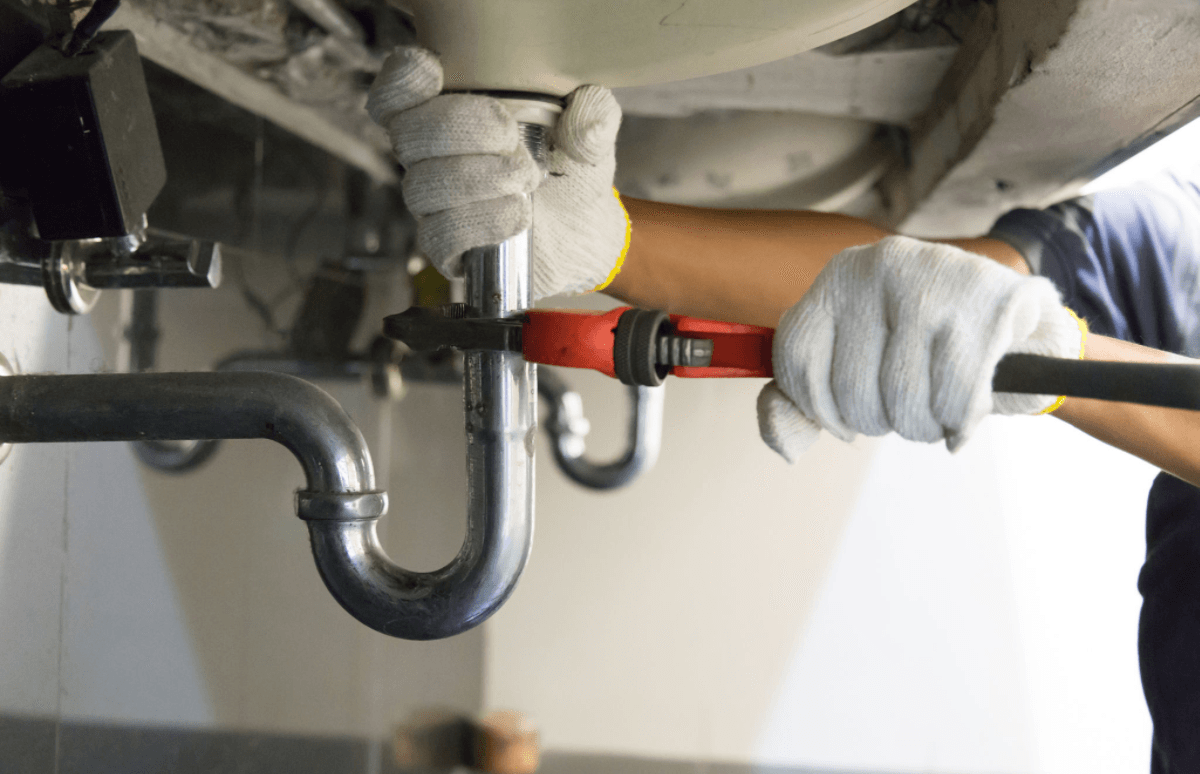

These devices are strategically installed at key points in the plumbing system, such as water service connections and irrigation systems. Their ability to respond quickly to changes in water pressure is critical in preventing the contamination of the clean water supply.

Regular Maintenance and Testing

To ensure the effectiveness of backflow preventers, regular maintenance, and testing are imperative. Certified professionals should conduct routine inspections to identify any signs of wear, damage, or malfunction. Prompt repairs or replacements are essential to maintain the efficiency of the backflow prevention system.

Compliance with Regulations

Given the vital role backflow preventers play in protecting public health and the water supply, adherence to local regulations and codes is essential. Many municipalities and governing bodies require periodic testing and certification of backflow preventers to ensure compliance and effectiveness.

In conclusion, backflow preventers act as a crucial line of defense against potential water contamination and health risks. Their proper installation, regular maintenance, and adherence to regulations are fundamental in upholding the integrity of our water supply and protecting the well-being of our communities. By utilizing the appropriate type of backflow preventer for each application and prioritizing their maintenance, we can ensure the continuous flow of clean and safe water for all.

Maintenance and Testing of Backflow Preventers

Regular maintenance and testing of backflow preventers are essential to ensure their proper functioning and effectiveness in safeguarding the integrity of our water supply. Over time, backflow preventers can experience wear, mechanical issues, or other problems that may compromise their ability to prevent backflow incidents. Implementing a comprehensive maintenance and testing regimen is crucial in maintaining the reliability of these devices and protecting public health.

Regular Inspections

Backflow preventers should undergo periodic inspections by certified professionals to assess their condition and functionality. These inspections typically involve checking for leaks, ensuring proper sealing, and verifying that all components are in good working order. If any issues are identified during inspections, prompt repairs or replacements should be carried out to maintain the efficiency of the backflow prevention system.

Frequency of Testing

The frequency of backflow preventer testing varies depending on local regulations and the type of backflow preventer installed. Generally, residential backflow preventers may require testing on an annual basis, while commercial and industrial backflow preventers may need more frequent testing. Consulting with local authorities or a certified plumbing professional can help determine the appropriate testing schedule for a specific property.

Winterization

In regions with colder climates, it is crucial to winterize backflow preventers to protect them from freezing temperatures. Frozen backflow preventers can become damaged and ineffective, leaving the water supply vulnerable to backflow incidents when the weather warms up. Winterization typically involves draining the backflow preventer and protecting it with insulation to prevent freezing.

Repair and Replacement

If a backflow preventer is found to be faulty, damaged, or beyond repair during inspections, it is essential to replace it promptly. Delaying replacement can leave the water supply susceptible to potential backflow incidents, compromising the safety of the drinking water.

Testing Procedures

Backflow preventer testing is a detailed process that involves checking the performance of each component. Certified testers utilize specialized equipment to simulate different backflow scenarios and ensure that the backflow preventer responds appropriately. The test results are recorded, and any necessary adjustments or repairs are made to bring the backflow preventer back to its optimal condition.

Compliance with Regulations

Adherence to local regulations regarding backflow preventer maintenance and testing is crucial. Many jurisdictions have specific requirements and timelines for testing, and failure to comply can result in penalties or fines. Staying informed about these regulations and maintaining accurate records of testing can help ensure compliance and protect against potential liabilities.

In conclusion, the proper maintenance and regular testing of backflow preventers are vital components of a comprehensive water management strategy. These proactive measures not only help protect public health but also demonstrate a commitment to ensuring the safety and purity of our water supply. By prioritizing the maintenance and testing of backflow preventers, we can rest assured that our water distribution systems remain robust and reliable, safeguarding the health and well-being of our communities for years to come.

Service By Scott: Protecting Tyler County’s Water Supply

In the heart of Tyler County, TX, stands a plumbing service provider that has been at the forefront of preserving the purity of the region’s water supply – Service By Scott. With a legacy of excellence and a commitment to delivering top-notch plumbing solutions, Service By Scott has become a trusted name in backflow prevention and plumbing services for residential, commercial, and industrial clients alike.

Expertise and Experience

Service By Scott boasts a team of highly skilled and certified plumbers with extensive expertise in backflow prevention and plumbing solutions. With years of hands-on experience, they possess an in-depth understanding of the complexities of backflow prevention systems, ensuring that each installation, maintenance, and testing procedure is carried out with precision and care.

Tailored Solutions for Every Setting

One of the standout qualities of Service By Scott is their ability to provide tailored backflow prevention solutions to meet the unique needs of each client. Whether it’s a residential property, a commercial establishment, or an industrial facility, the team at Service By Scott leverages their knowledge to recommend and implement the most suitable backflow preventer for optimal protection.

Compliant with Regulations

Service By Scott places the highest priority on compliance with local regulations and codes related to backflow prevention. They stay up-to-date with the latest industry standards and ensure that all backflow preventers installed and maintained by their team are in full compliance with applicable regulations. This commitment to compliance not only protects clients from potential legal issues but also contributes to the overall safety of the community’s water supply.

Prompt and Reliable Service

When it comes to backflow prevention and plumbing services, timeliness is of the essence. Service By Scott understands the importance of prompt action, especially when addressing potential backflow incidents or emergencies. Their team is equipped to respond swiftly to service calls and is dedicated to resolving issues efficiently, reducing downtime, and minimizing any disruption to the water supply.

Customer-Centric Approach

Service By Scott takes pride in its customer-centric approach. They prioritize communication, actively listen to their client’s concerns, and work collaboratively to find the best solutions for their specific needs. With a focus on building lasting relationships, they aim to ensure that each client receives personalized attention and exceptional service throughout their experience with the company.

Advocates of Water Safety

Beyond providing top-tier backflow prevention services, Service By Scott is also actively involved in raising awareness about water safety within the community. They educate their clients about the importance of backflow prevention and the potential risks associated with cross-connections. Through educational initiatives and outreach programs, Service By Scott strives to empower individuals and businesses to take proactive steps in safeguarding their water supply.

In conclusion, Service By Scott is not just a plumbing service provider; it is a dedicated guardian of Tyler County’s water supply. Through their expertise, commitment to compliance, and customer-centric approach, Service By Scott has earned the trust of countless clients who rely on their knowledge and skill in backflow prevention. As they continue to champion water safety and deliver exceptional plumbing services, Service By Scott remains an invaluable asset to the community, ensuring that clean and uncontaminated water flows freely into the homes and businesses of Tyler County.

Conclusion

In conclusion, Service By Scott stands as an unwavering protector of Tyler County’s water supply, championing the cause of water safety and ensuring that clean and uncontaminated water flows freely into homes, businesses, and industries. With a team of highly skilled and certified plumbers, a commitment to compliance with regulations, and a customer-centric approach, Service By Scott has established itself as a trusted name in backflow prevention and plumbing services.

As a resident, business owner, or property manager in Tyler County, you have the power to take proactive steps in safeguarding your water supply. Whether you need a new backflow preventer installation, regular maintenance, or testing services, Service By Scott is here to help. Don’t wait for potential backflow incidents to occur – be proactive and ensure the safety of your water supply today.

Contact Service By Scott now to schedule a consultation and discover how their expert team can tailor a backflow prevention solution to meet your specific needs. Protecting the health and well-being of your loved ones, customers, and employees starts with taking action to safeguard your water supply. With Service By Scott by your side, you can rest assured that your water distribution system is in capable hands.

FAQs

What is backflow, and why is it a concern?

Backflow is the undesirable reversal of water flow within a plumbing system, which can lead to the contamination of the clean water supply with non-potable water, pollutants, and harmful substances. It is a significant concern as it poses health risks and compromises the safety of drinking water.

How can backflow incidents be prevented?

Backflow incidents can be prevented by installing backflow preventers in the plumbing system. These devices create a barrier that stops the reverse flow of water, ensuring that contaminants cannot enter the potable water supply.

Are backflow preventers necessary for residential properties?

Yes, backflow preventers are essential for residential properties. They protect households from potential waterborne illnesses caused by backflow incidents, ensuring that the water used for drinking, cooking, and bathing remains safe and uncontaminated.

How often should backflow preventers be tested?

The frequency of backflow preventer testing varies depending on the type of backflow preventer and local regulations. In general, residential backflow preventers may require annual testing, while commercial and industrial settings may need more frequent testing.

Can I install a backflow preventer myself?

While some residential backflow preventers may be available for DIY installation, it is highly recommended to hire a certified plumbing professional for proper installation and testing. Incorrectly installed backflow preventers may not provide adequate protection and could lead to compliance issues with local regulations.